The surface roughness during milling depends, among other things, on the design of the insert, cutting and feeding speed, and the number of inserts and vibration

The theoretical surface roughness can be calculated by the tool's nose radius, feed rate, rotation speed and number of inserts.

However, actual surface roughness is affected by vibrations in the tool or machine, tool wear, chip types, and cutting position variations in milling tools with more than one cutting insert.

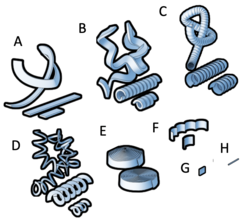

Chip Types

Surface roughness