The Thermal cutting techniques all have interchangeable nozzles at the tip of the cutting head

The purpose of the nozzles is to direct cutting gases and protective gases to the area being cut and to blow away molten material.

A suddenly worsened cutting result is often caused by a nozzle being contaminated or deformed by physical impact, which results in a deviated gas flow.

The nozzles are interchangeable in order to be quickly replaced after damage or to be replaced by another type, for example nozzle with larger hole diameter or other hole distribution, adapted to the workpiece material type or thickness.

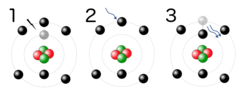

The illustration shows examples of nozzles for ...

1. Laser cutting

2. Plasma cutting (often with built-in channels for water cooling)

3. Flame cutting

LASER