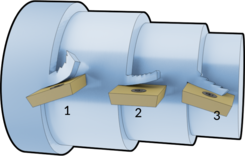

During rough machining [1], the aim is high removal rate and in the case of fine machining [2], the final desired tolerance is achieved

Machining of a workpiece is generally divided into one or two levels of roughness. The first level can be for a first pass over a workpiece's uneven surface, which gives rise to varying chips, large cutting forces and chock forces.

Thereafter, a more optimized level of rough turning is often performed to as high removal rate as possible to achieve near final shape.

The machining is then completed with a finishing pass to finalise the dimensions and tolerances.

The different levels make different demands on the inserts and cutting angles where, for example, negative rake inserts are best suited for coarse machining since they have a better ability to absorb cutting forces which allows higher cutting speeds. With finish machining, positive rake inserts are usually chosen which give a better surface finish but at the expense of removal rate.

for more info see technical term Positive and negative rake angle in turning as well as Positive and negative rake angle in milling.

In optimum conditions, the workpiece's original dimensions are so close to the final shape (called near-net-shape) that only finishing is required to complete the detail.