Automatic line casting

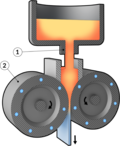

Process Forming process where mold halves are stacked above each other to form a series of intermediate molds.

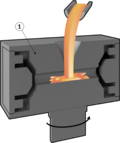

Gjutning av metall innebär att en vanligtvis fast metall upphettas till smält tillstånd. Smältan hälls eller trycks därefter i en engångsform som skapas inför varje gjuttillfälle alternativt en permanent form som kan återanvändas flera gånger.

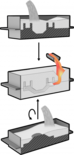

Efter att smältan stelnat så avlägsnas formen för att frilägga den färdiga detaljen.