Lost foam casting

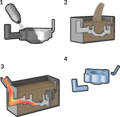

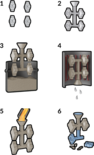

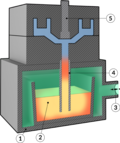

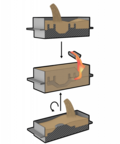

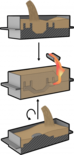

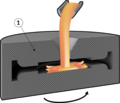

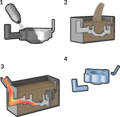

Process Forming process in which molten material is poured on a polystyrene detail surrounded by a ceramic shell is immersed in the sand.

Gjutning av metall innebär att en vanligtvis fast metall upphettas till smält tillstånd. Smältan hälls eller trycks därefter i en engångsform som skapas inför varje gjuttillfälle alternativt en permanent form som kan återanvändas flera gånger.

Efter att smältan stelnat så avlägsnas formen för att frilägga den färdiga detaljen.