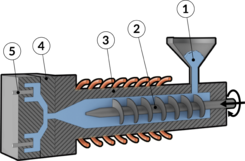

Cutting tool made of cemented carbide powder that is pressed or metal injection molded (MIM) followed by sintering

By pressing or metal injection molding (MIM) followed by sintering cemented carbide powder, mainly tungsten carbide and cobalt, is formed into inserts which, compared to High Speed Steel, have a better ability to maintain their properties at higher temperatures, which enables increased cutting speed. These inserts, also called indexable inserts, are mounted on a cutting tool holder and can be repositioned to use different cutting edges before being discarded.

The cemented carbide inserts are usually coated with one or more surface layers which increase the wear resistance of the insert. The surface coats are usually applied by chemical vapor deposition (CVD) or Physical Vapor Deposition (PVD).

There are six different ISO classifications of workpiece material for cutting which helps the user to choose the right cutting tool. Roughly, these can be divided into:

- P : Steel

- M : Stainless steel

- K : Cast iron

- N : Non-ferrous metals

- S : Super & Titanium Alloys

- H : Hardened steel

In addition, there are other designations that indicate the shape of the insert, release angle, tolerance class, chip breaker, holding model, size, cutting direction etc.