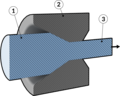

Profile rolling

Process Rolling process in which the workpiece passes through a series of rollers that gradually shapes the workpiece into the required profile.

Deformering med pålagd kraft som omformar materialet till sådan grad att det ej återgår till sin ursprungliga form efter att kraften avlägsnats.