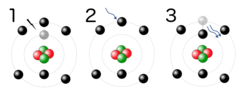

The angle of the two cut surfaces relative to each other

Depending on the thermal cutting method used, different parallelities can be achieved between the two cut surfaces that occur after the cutting, a so-called angular deviation.

The angular deviation is greatest for plasma cutting and least for Laser and Gas cutting. An advantage of parallel cutting surfaces is that you have better conditions for being able to share cutting contours between parts which increases productivity and minimize material waste.

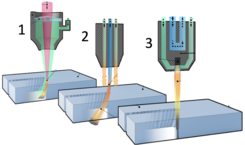

By using a tiltable cutting head you can compensate for this angular deviation and thus creat a perpendicular cut on the strived detail leaving the deviation on the scrap piece.

LASER

Thermal cutting