Cutting fluid has three main purposes. Cooling, lubrication and removal of chips.

Cooling

The fluid's high thermal conductivity makes it a good coolant.

The cooling of the tool reduces the risk of overheating which would lead to faster wear. It reduces the workpiece's thermal expansion and provides a better chip breaking.

Lubrication

The fluid's lubricating ability leads to reduced cutting forces, argued by some, by lowered frictional resistance and reduced deformation forces in the material.

Chip removal

The fluid also helps to remove chips that might otherwise interfere with the manufacturing process.

Other effects

Cutting fluid has in addition to these three areas other positive characteristics such as corrosion resistance and smoke suppression.

Application

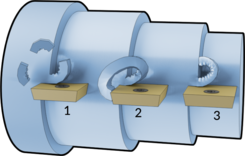

The cutting fluid is sprayed either against the workpiece or the tool by adjustable outer spray nozzles. Many tool holders and tools also have internal channels that provide improved cooling and chip removal to the cutting spots.

Types of cutting fluids

Water-mixable cutting fluids consist of a mixture of water and synthetic or mineral oils.

Non-water-mixable cutting fluids, also called cutting oils, consist of an oil or oil mixture.