Penetration of the work piece

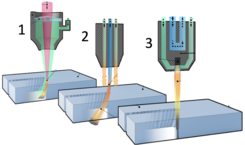

In thermal cutting, thecut can be initiated from the edge of the plate or by burning holes through the surface of the plate, so-called piercing.

During piercing, the metal is heated to melting temperature and thrown up using the pressure of the shearing gas, which results in a crater with slag splashes around it. The splashes can also cause contamination of the nozzle which may affects the gas flow with poor cutting results as a result.

Slag that get stuck to the surface may interfere with the subsequent cutting of the contour. The problem is increased for cutting thicker sheets and can sometimes be so suvere that one have to perform a so-called "pre-piercing" where all piercings are done separately followed by slag removal befor cutting the contours.

Thermal cutting