A relative measure of how easily a material can be shaped by cutting

A material with good machinability is sought to obtain the best production economy possible where stable process and rapid removal are two important parameters.

A material's machinability is defined and affected by a number of parameters.

Tool wear

This is the most important parameter since wear of cutting tools has a direct impact on the machining result. Reduced wear contributes to better machinability.

Cutting resistance

Large cutting resistance requires large cutting forces, which affects achievable tolerances due to elasticity and vibrations in the workpiece and the machine. The large forces also increases the risk of tool failure while increasing the energy demand.

Lower cutting resistance contributes in most cases to better machinability.

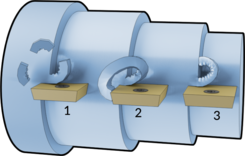

Chip breaking

The kind of chips formed and how they break depends largely on the material. Small chips are preferable to reduce the risk of snarls that can affect the cutting result while it facilitates chip removal.

Shorter chips contributes to improved machinability.

Built-up edge

The tendency of a material to accumulate on the insert surface, also called built up edge formation, negatively affects the cutting result.

Lower tendency for built-up edge formation improves machinability.

Surface finish

A material that allows for higher tolerances and with less tendency to micro-cracks in the surface contribute to improved machinability.

Determination of a material's machinability

There is currently no standardized method for determining the material's machinability, which is why this act as comparative scale between different materials from the same supplier..