HAZ stands for Heat Affected Zone, which is the area of a metal affected by a local heating

During welding and thermal cutting, for example, the metal quickly heats up to its melting point in a local area and is then rapidly cooled down due to surrounding colder materials. This results in a change in the microstructure of metals and thus also its material properties.

Built-in tentions, microcracks and impaired corrosion resistance can also occur, which in turn increases the risk of failure of deatils under load.

The extent of the HAZ effect is mainly based on cutting temperature, heated area and cutting speed, which means that laser cutting results has the least HAZ, gas cutting the greatest and plasma cutting in between.

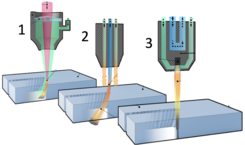

LASER

Thermal cutting